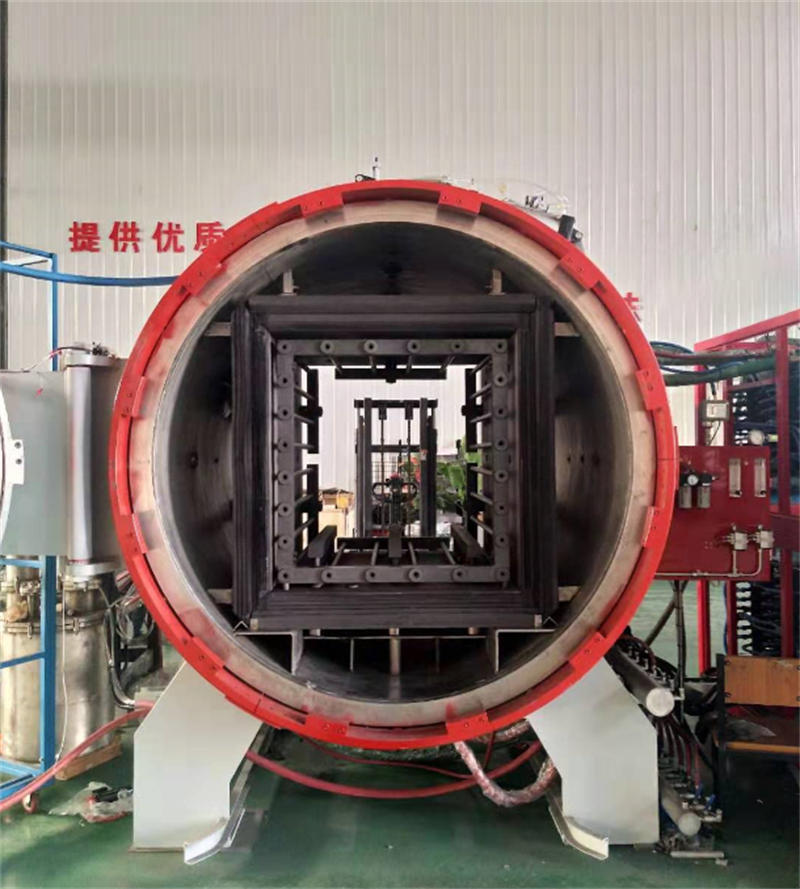

Brand:Sincere

Model: Vacuum furnace

Place of Origin: Ningxia, China

Whether to export: yes

Custom processing: Yes

LW612 high temperature and high vacuum sintering furnace: lw612 is a multifunctional high temperature experimental equipment with ultra-high temperature, ultra-high vacuum and multi atmosphere (nitrogen, hydrogen, argon, etc.). The equipment can realize high temperature experiments in vacuum, ultra-high vacuum, hydrogen and other atmospheres. The equipment adopts all metal hot zone, oil-free ultra-high vacuum Pfeiffer molecular pump, high-performance Honeywell programmable control system, hydraulic furnace lifting system, etc. The equipment has the advantages of simple appearance, small floor area, high degree of automation, excellent safety performance, simple and convenient operation, etc.

Performance characteristics: uniform temperature zone φ 300 * 600mm, the highest temperature is 2600 ℃, and the vacuum degree can reach 5.0 × 10-8Torr。 Users can set the way to realize vacuum sintering, atmosphere sintering or combined sintering. According to the process needs, temperature rise curve and process gas flow curve can be set. It is suitable for different sintering processes of various high-temperature materials. The gas flow can be set and adjusted automatically according to the temperature. The whole process of experimental data can be recorded automatically. It supports remote operation and online monitoring, with stable performance and safe use.

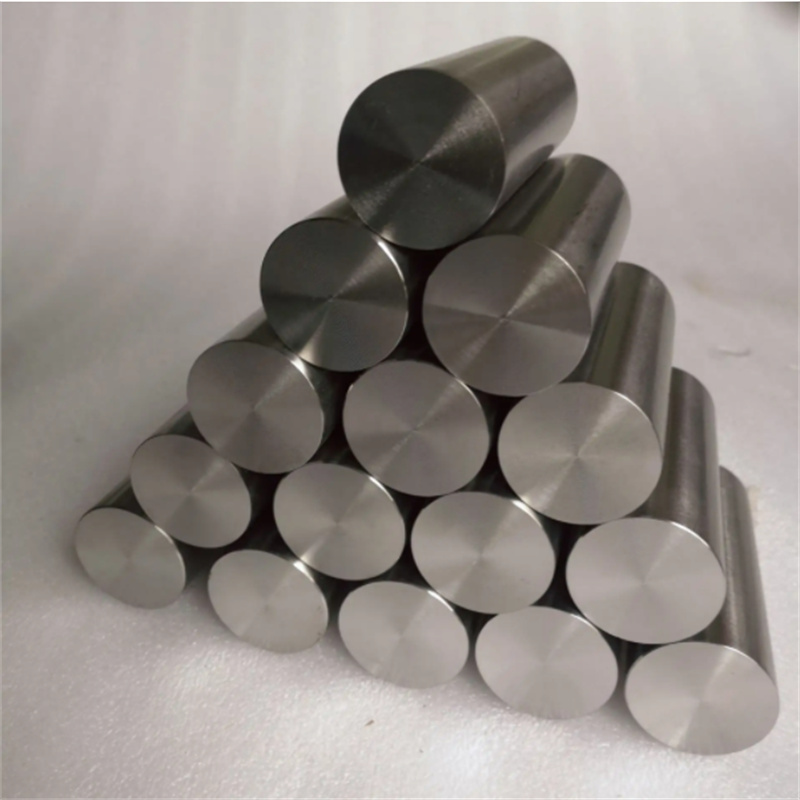

Application: used for sintering experiments of materials under ultra-high temperature and high vacuum environment, including "sintering of high temperature ceramics such as AlN and Si3N4, process experiments and production of high temperature metal heat treatment and powder metallurgy sintering."