Product description

Silicon Carbide Sand/Granular

Silicon Carbide Sand/Granular

Rongchang silicon carbide sand is produced using black silicon carbide blocks through a series of processes such as crushing, shaping, pH testing, magnetic separation, and screening, and has a variety of particle sizes.

This silicon carbide has the characteristics of regular particle shape, clustered particle size, high bulk density, and high particle surface cleanliness.

1. This product is produced in accordance with the international standard GB/T2481.1-GB/T2481-1998 and compatible with European FEPA and American AIVSI standards.

2. Granular sand and refractory sand with different bulk density can be processed according to customer requirements.

Product Usage: Used to make Grinding Wheels, Cutting Blades, Wear-Resistant and Corrosion-Resistant Materials, FRP Pipes, Blasting Sand and Casting Materials, etc.

Silicon Carbide Powder

Rongchang Silicon carbide powder is a silicon carbide powder product of more than 100U formed after being crushed by the raw silicon carbide by Raymond machine, jet mill, ball mill, and shaping machine, and then classified into products of different international standards by overflow method.

Its air particle hardness can reach 2800-3300KG/mm². High purity, low impurity content, high cleanliness of particle surface, and particle size clusters.

Product Usage:

1. It is an important raw material for manufacturing high-grade refractory materials, high-temperature ceramics, resistance heating elements, abrasives and recrystallized silicon carbide products.

2. Various types of ultra-fine silicon powder crushed and classified by jet mill will achieve ideal results in ultra-fine grinding and polishing.

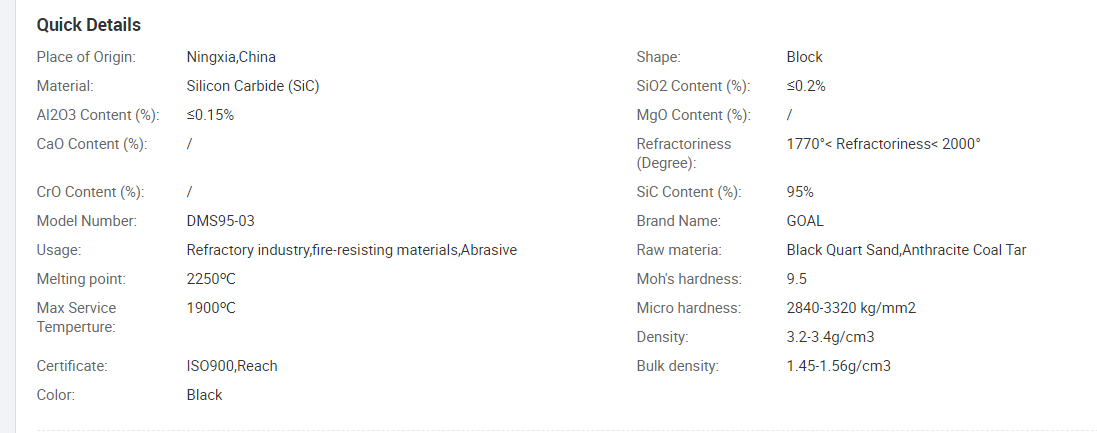

Silicon Carbide Block

Black silicon carbide, with metallic luster, has a molecular formula of SiC and contains about 98.5% of SiC. Its toughness is higher than that of green silicon carbide. It is made from quartz sand and anthracite as the main raw materials and smelted at high temperatures in a resistance furnace.

It is a black opaque body, hexagonal crystals, with a Mohs hardness of 9.15-9.5, which is higher than corundum in abrasives and second only to diamond and boron carbide.

High mechanical strength, stable chemical performance, high thermal conductivity, low thermal expansion coefficient, good wear resistance, and certain electrical and thermal conductivity.

Rongchang silicon carbide block uses high-quality anthracite and high-purity quartz sand from Helan Mountain in Ningxia as raw materials, uses a large resistance furnace body, and uses high-power smelting technology to produce high-purity, large-crystalline black silicon carbide. Its crystallization is more complete and the product is The physical and chemical indexes and performance are significantly higher than those of general products.

Product Usage: Used for making abrasive tools and processing metal and non-metal materials with low tensile strength. Such as: gray cast iron, glass, ceramics, stone, refractory materials and non-ferrous metals.