Product description

Silica powder (also known as silica fume, silica powder, micro silica powder)

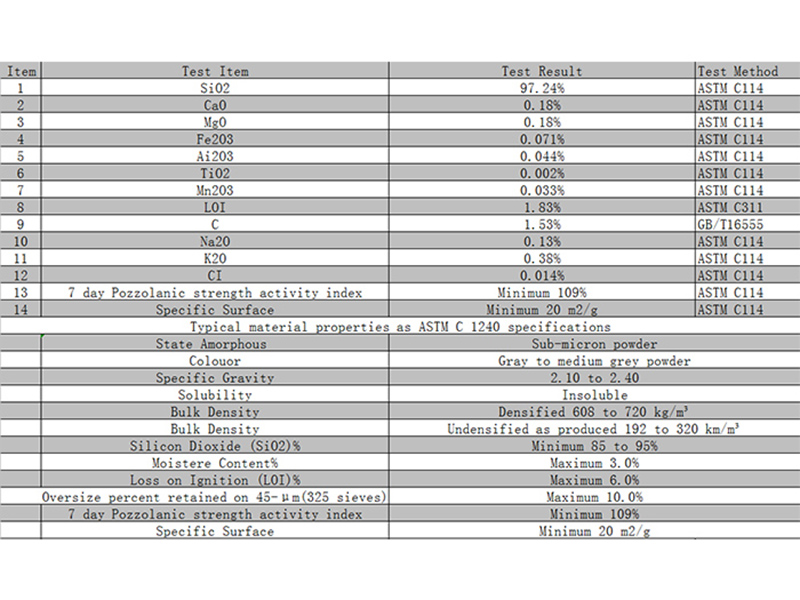

silica content: SiO2% 80%---95%

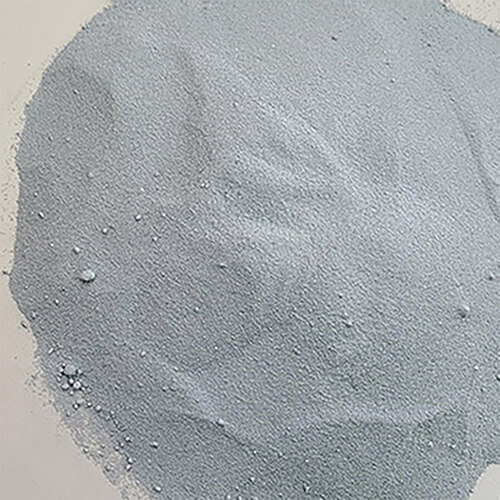

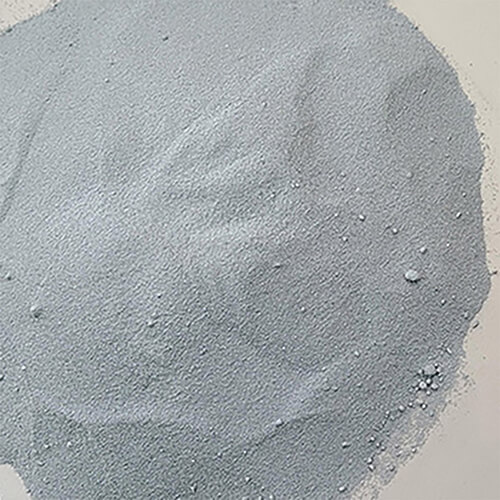

Silicon powder is a kind of industrial furnace in the process of smelting industrial silicon and ferrosilicon at high temperature. The dust escaping from the exhaust gas is collected and processed by bag collecting device. It is named "silicon powder", microsilica or silica fuse. The proportion of SiO2 content in the total smoke is between 85% and 95%, the particle size is small and the particle size distribution is uniform, and the specific surface area is between 15000-25000cm². Because of the large specific surface area of silica, different customers have requirements for the density of silica. We provide different density silicon powder to customers.

In concrete, it is mainly used to improve the strength of concrete. Although HPC with compressive strength up to 100 MPa can be made with pure cement, it will be much easier when silica fume is used. For the preparation of concrete with strength over 100 MPa, the use of silica fume is almost indispensable. Silica fume is used as filling material and pozzolanic material in concrete at the same time. After the use of silica fume, the pore size in the hydration paste is greatly reduced, and the pore size distribution is improved, so the strength is improved and the permeability is reduced, and the absolute strength of silica fume concrete is higher than that of pure cement concrete.

Compared with the silicon powder produced in ferroalloy smelting, the silicon powder produced in metal silicon smelting usually has a higher content of silicon dioxide, but its pozzolanic activity is generally low due to its uniform fineness, uneven particle size distribution and narrow particle grading range.Therefore, in the dust collection site selection, our company chooses to collect silicon powder in the ferroalloy smelting plant, and chooses the silicon dioxide content higher than 90% as our main products. As commercial concrete additive material, high activity is our first choice. At the same time, the silicon content higher than 90% is our main advantage to distinguish our products from other competitive products.