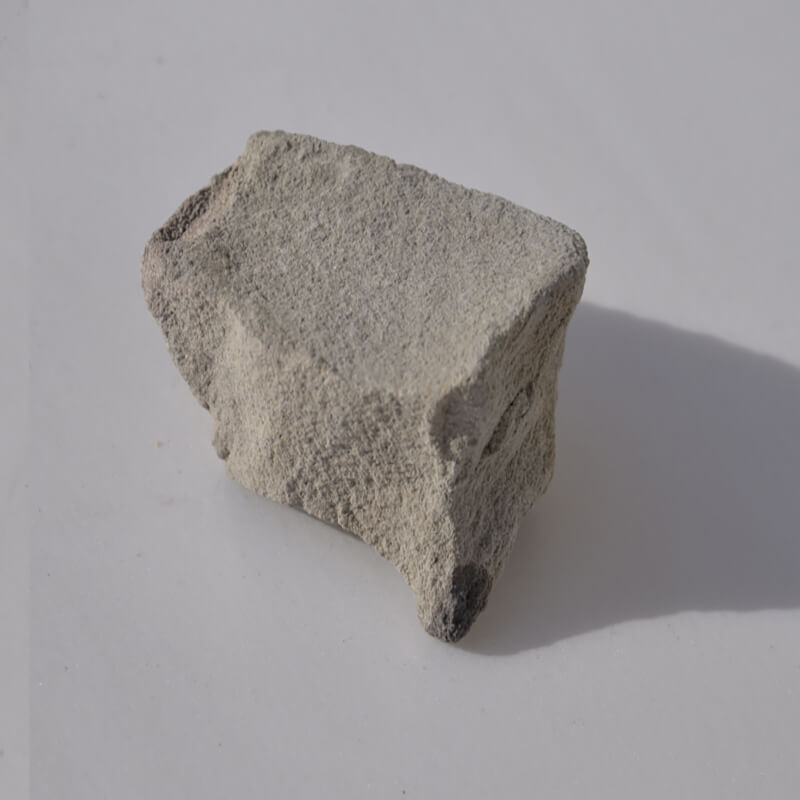

ilicon nitridide, a light gray, inorganic non-metallic raw material, has a very good application in iron and steel smelting, refractory materials, etc., abrasion resistant rubber, plastic, ceramics and other sealing abrasive has a wide range of applications at room temperature and high temperature.

1. Main Features This product is a new material produced at a specific atmosphere temperature. Main features: first, it has good corrosion resistance, thermal conductivity, thermal shock resistance and wear resistance. Can be used at temperatures below 1800 degrees Celsius. Second, it has excellent splitting endurance, very stable chemical composition and thermal conductivity. Third, it has the advantages of small expansion coefficient, large thermal conductivity and large strength. Fourth, high temperature oxidation resistance is good.

2. Advanced production technology. Our company silicon nitride production using international production process, to achieve batch stable production, can long - term low - price, high - quality supply.

3. The products are widely used. As a new profile of modern industry, si3n4 powder is widely used in ceramics, refractory, iron and steel metallurgy, non-ferrous metallurgy, rubber and other industries. Such as:

1) In the nonferrous industry, its corrosion resistance and erosion performance is very excellent, widely used.

2) In the steel industry

Silicon nitride

A. Silicon nitride coating can effectively solve the problem of oxidation and burning loss of billet during heat treatment. The experimental results show that the anti-oxidation effect of nano-silicate anti-oxidation coating is obvious, which can reduce the oxide scale of 3%-5% produced by ordinary hot rolled plate to 0.1-0.8%, and reduce the oxide scale of 1%-3% produced by stainless steel hot rolled plate to 0.2%.

B. Silicon nitride shotcrete. The blasting mud containing si3N4 will play an effective role in sintering activation, corrosion resistance and splitting resistance. It can seal the blast furnace mouth more stably in furnace or electric furnace and is very easy to cut.

C. Silicon nitride has a good application in HRB400 high strength hot rolled steel bar. Si3N4 as nitrogen increasing agent, cooperate the FeV used in the production of V microalloyed Ⅲ grade steel, reinforced high performance stability, is the production of HRB400 grade Ⅲ reinforced a new alloying process.

D. Silicon nitride is second only to boron nitride in the content of nitrogen per unit mass, and its price is relatively low, so it has a very high cost-performance ratio in terms of nitrogen increment.

3) Due to the good application of this product in new ceramics and composite materials, its corrosion resistance, heat conduction, heat resistance, abrasion resistance, high strength and other properties are improved.

4. Chemical properties in use. Silicon nitride has very high temperature stability. High corrosion resistance under acidic conditions. It is highly alkaline resistant at temperatures up to 500 degrees Celsius.