Product Details

Micro silicon powder, also known as silica fume or condensed silica fume, is a type of iron alloy that produces a large amount of highly volatile SiO2 and Si gas in the smelting of ferrosilicon and industrial silicon (metallic silicon) in the electric furnace. After the gas is discharged, it quickly oxidizes, condenses and precipitates with air. It is a byproduct in large-scale industrial smelting, and the entire process requires the use of dust removal and environmental protection equipment for recycling. Due to its low density, encryption equipment is also needed for encryption.

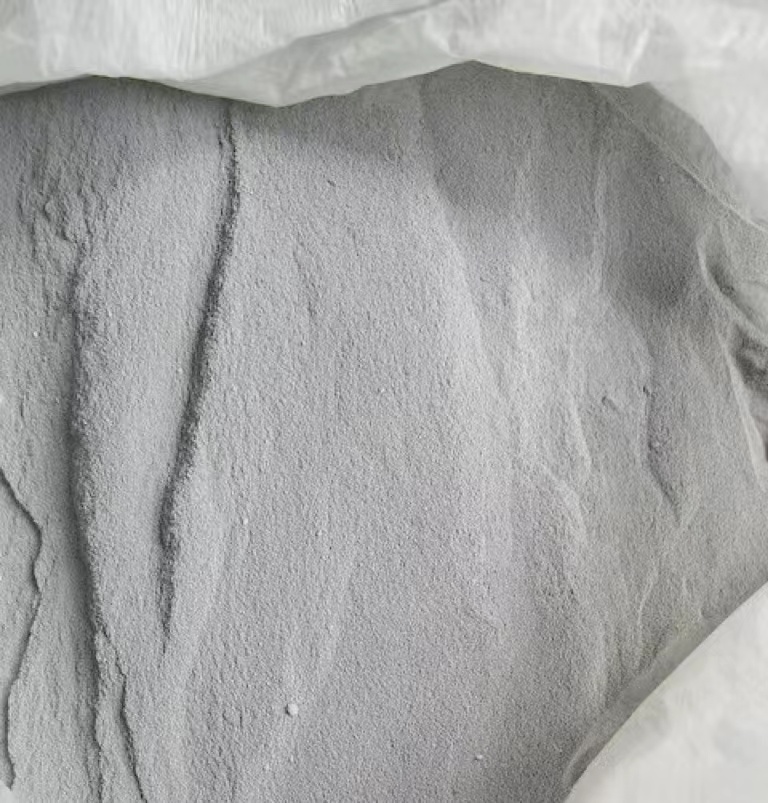

In terms of particle size, silicon micro powder is processed from natural quartz and has a relatively large particle size, including 200 mesh, 300 mesh, 400 mesh, 500 mesh, 600 mesh, 800 mesh, 1000 mesh, 1250 mesh, 3000 mesh, 5000 mesh, 10000 mesh, etc. It is a powder state. And the fineness of micro silicon powder is less than 1 μ M accounts for over 80%, with an average particle size ranging from 0.1 to 0.3 μ m. It is a gray state.

Silica fume: basic chemistry and multiple advantages

Silica fume is a co-product of silicon or ferrosilicon production, consisting of ultrafine (sub-micron), amorphous, non-porous, perfectly spherical silicon dioxide (SiO2) particles, with purity levels of 85 to 99 %. The main effect of these ultra-fine particles is to greatly improve particle packing and produce a highly pozzolanic reaction in concrete and other cementitious bond systems where the silicon dioxide reacts with calcium hydroxide, heightening performance levels and the strength and durability of these materials. Additionally, silica fume, because of its amorphous (non-crystalline) structure and its specific area, provides other useful features to various applications, including improved sintering capabilities and enhanced high temperature performance of refractory castables, resulting in reactions between microsilica and other components of the refractory mix.

To summarize, silica fume has two key features which alone or in combination are the basis for its high performance:

- The nano-sized spherical non-porous particles create an efficient “filler effect”

- Primary particles have an average diameter of about 0.15 μm (150 nanometers)

- Microsilica is a highly reactive form of silica producing a “chemical effect”

- Thanks to its amorphous nature and high specific surface area.

A review of some leading products and applications in different industries

Applications are very numerous, including uses in construction, well drilling & cementing, refractories, polymers, etc. This versatility also explains why silica fume is referred to by different names in different industries, such as condensed silica fume or microsilica, the latter used, for example, in High-Performance Materials (HPM) in the construction and refractory industries.