Product Description

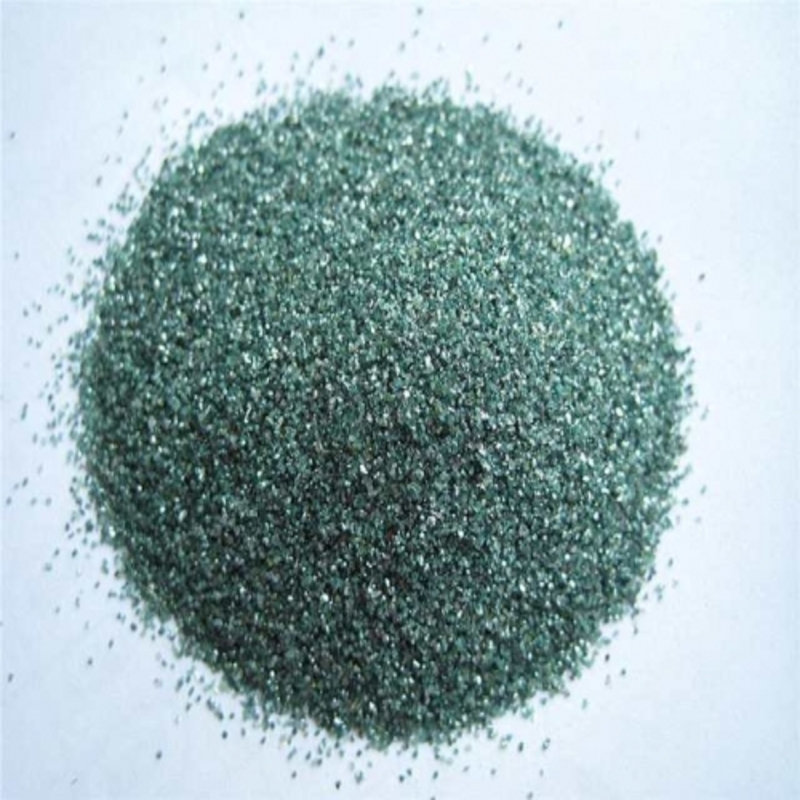

Silicon carbide also exists in nature as a rare mineral, moissanite. Silicon carbide is also known as carbon silica. In contemporary C, N, B and other non-oxide high technology refractory raw materials, silicon carbide for the most widely used, the most economical one, can be called gold steel sand or refractory sand. At present, China's industrial production of silicon carbide is divided into two kinds of black silicon carbide and green silicon carbide, both hexagonal crystal, specific gravity of 3.20 ~ 3.25, microhardness of 2840 ~ 3320kg/mm2.

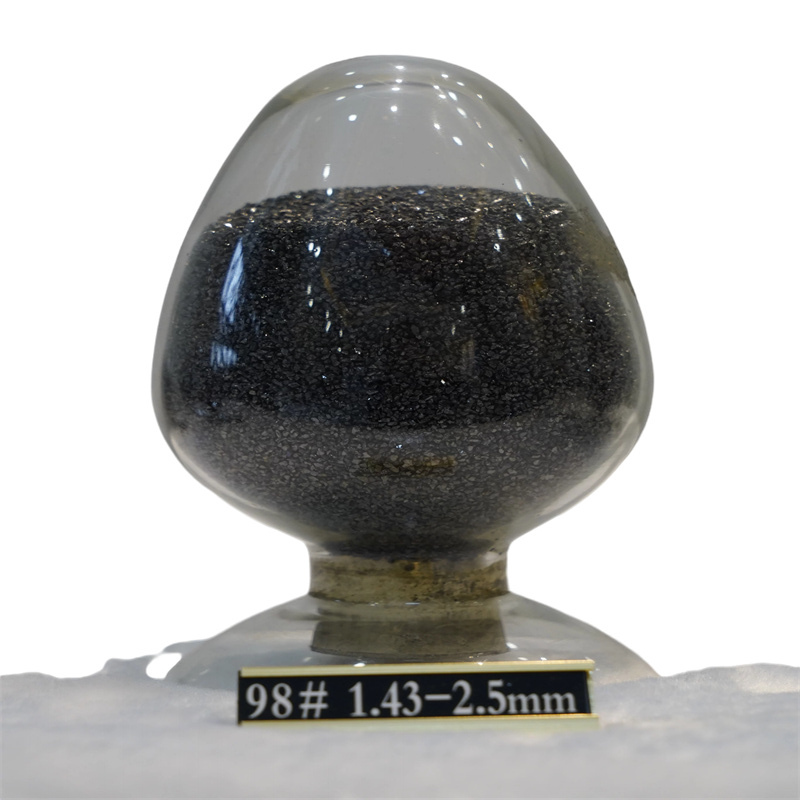

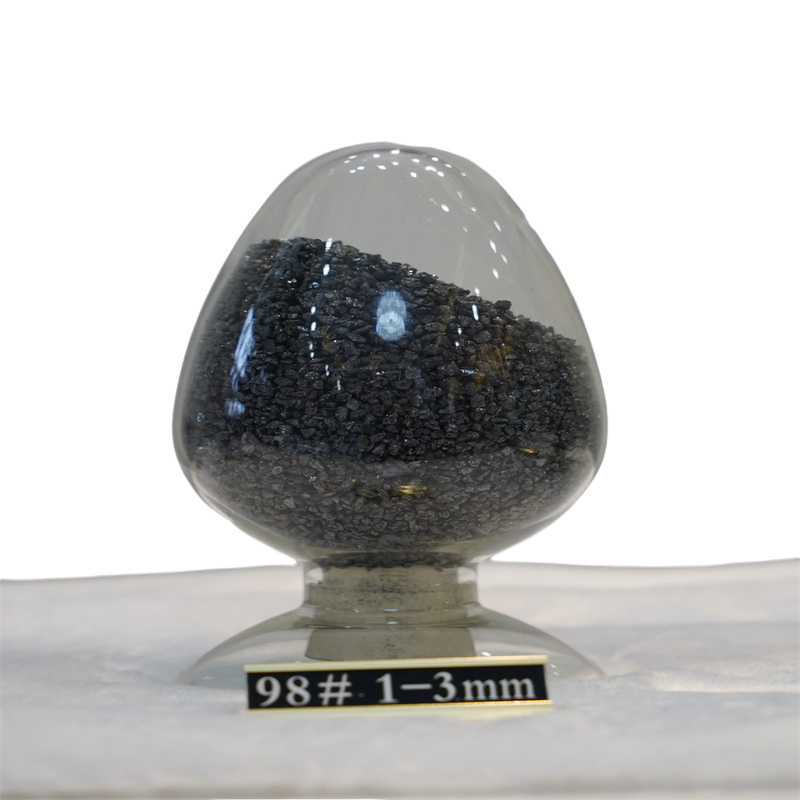

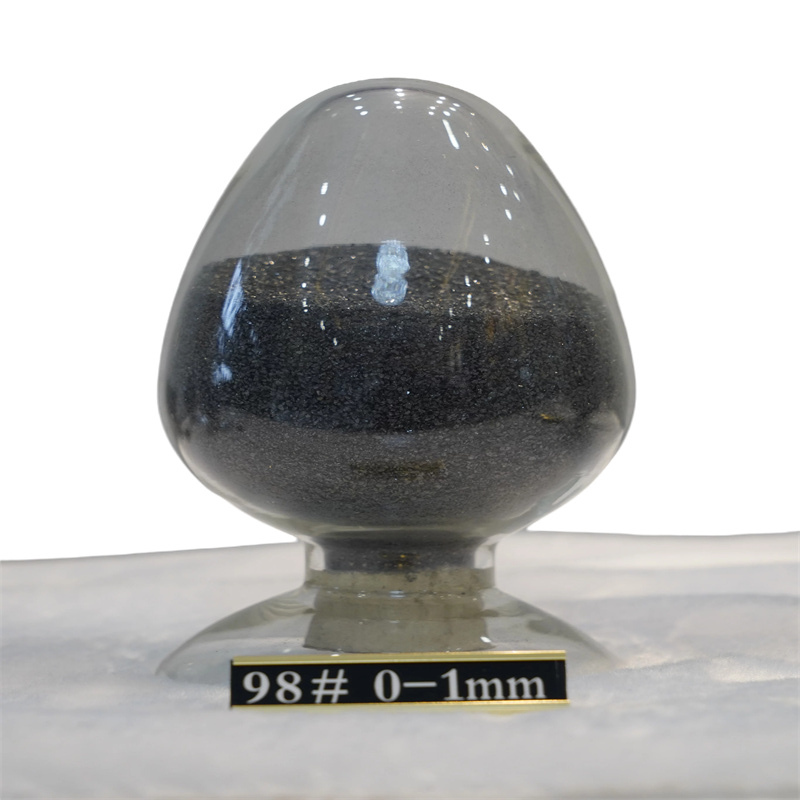

Black silicon carbide

Content:98#、97#、95#、90#、88#、75#、70#

Size:(mm)0-0.1、0-0.2、0-0.5、0-1、0-3、0-5、0-10、0.2-0.5、0.5-1、1-2、1-3、2-3、1-5、1-10

Mesh:120、150、170、180、200、240、325、

Example: Silicon Carbide 0-0.5mm (others can be inquired)

SiC% | FC% | Fe2O3% | FSi% | SiO2% | CaO % | MgO % | AL2O3% | S % | H2O% |

≥98.0 | ≤0.15 | ≤0.25 | ≤0.8 | ≤0.5 | ≤0.1 | ≤0.01 | ≤0.15 | ≤0.03 | ≤0.3 |

≥97.0 | ≤0.30 | ≤0.4 | ≤0.8 | ≤1.2 | ≤0.2 | ≤0.02 | ≤0.30 | ≤0.04 | ≤0.5 |

≥95.0 | ≤1.0 | ≤1.0 | ≤0.8 | ≤1.5 | ≤0.5 | ≤0.05 | ≤0.40 | ≤0.05 | ≤0.5 |

Purpose

(1)The Mohs hardness of silicon carbide is as high as 9.2-9.5, second only to diamond. The hardness is higher than that of all common metals, alloys, stones and optical glass materials. It can be used to make grinding tools such as silicon carbide grinding wheels, silicon carbide oilstones and silicon carbide sandpaper. Silicon carbide grinding wheels are superior to white alumina and brown alumina grinding wheels, with better grinding and cutting efficiency, good durability, long service life, and moderate price.

(2)Silicon carbide is a high-performance refractory material. Silicon carbide is used for refractory castables, refractory bricks, refractory plates, industrial furnace heat exchangers, silicon carbide crucibles, silicon carbide nozzles, etc.

Package

Various sizes of packaging can be developed according to customer requirements.

We use anthracite smelting silicon carbide, which has high SiC content, stable physical and chemical indicators, and high crystallization density. High quality and dense silicon carbide products have a content of up to 99%, a specific gravity greater than 3.2g/cm3, and a bulk density greater than 1.72g/cm3.

SILICON CARBIDE PROCESSING PROOUCTINOICATORS | ||||

| Grade | SIC(%) | F.C(%) | Fe2O3(%) | H2O (%) |

| 99# | ≥99.00 | ≤0.10 | ≤0.10 | ≤0.10 |

| 98# | ≥98.00 | ≤0.25 | ≤0.30 | ≤0.30 |

| 97# | ≥97.00 | ≤0.30 | ≤0.40 | ≤0.30 |

| 95# | ≥95.00 | ≤1.00 | ≤1.00 | ≤0.30 |

| 88# | ≥88.50 | ≤2.80 | ≤3.00 | ≤0.50 |

| 70# | ≥70.50 | ≤8.00 | ≤3.50 | ≤1.00 |

Sales network