Main parameters

Low partial discharge

Through rounding treatment of core clamps, tank seams, and lead connections,combined with molded angle rings, the product's partial discharge is effectivelycontrolled.

Low loss

Guided by electromagnetic field simulation results, magnetic shielding is designed atcritical locations. Through the application of low-permeability materials and othertechnical measures, stray losses caused by leakage flux are minimized, the internalelectromagnetic environment is optimized, and overall losses are reduced-ultimatelyleading to significant operational cost savings for users.

Low noise

Both the core and active part are designed with vibration-damping pads,incorporating a multi-point positioning structure to effectively reduce operationalvibrations. This achieves noise levels significantly below standard requirements.

Reliability

By utilizing premium insulating materials combined with our proprietary insulationstructure design and advanced manufacturing processes, we ensure reliable electricalclearance under high voltage conditions.

Low partial discharge

Through rounding treatment of core clamps, tank seams, and lead connections,combined with molded angle rings, the product's partial discharge is effectivelycontrolled.

Low loss

Adopting high-permeability silicon steel sheets and a fully-enclosed insulationstructure, the design achieves reduced no-load losses and highly efficient and stableoperation. With optimized electromagnetic layout and multi-layer protection, thetransformer demonstrates low temperature rise, minimal noise emission, andcomplies with safety, energy-saving,and environmental standards.

Low noise

Both the core and active part are designed with vibration-damping pads,incorporating a multi-point positioning structure to effectively reduce operationalvibrations. This achieves noise levels significantly below standard requirements.

Reliability

By utilizing premium insulating materials combined with our proprietary insulationstructure design and advanced manufacturing processes, we ensure reliable electrical

clearance under high voltage conditions.

Low partial discharge

Through rounding treatment of core clamps, tank seams, and lead connections,combined with molded angle rings, the product's partial discharge is effectivelycontrolled.

Low loss

Guided by electromagnetic field simulation results,magnetic shielding is designed atcritical locations. Through the application of low-permeability materials and othertechnical measures,stray losses caused by leakage flux are minimized, the internalelectromagnetic environment is optimized, and overall losses are reduced-ultimatelyleading to significant operational cost savings for users.

Low noise

Both the core and active part are designed with vibration-damping pads,incorporating a multi-point positioning structure to effectively reduce operationalvibrations. This achieves noise levels significantly below standard requirements.

High reliability

By utilizing premium insulating materials combined with our proprietary insulationstructure design and advanced manufacturing processes, we ensure reliable electricalclearance under high voltage conditions.

Low partial discharge

Through rounding treatment of core clamps, tank seams, and lead connections,combined with molded angle rings,the product's partial discharge is effectivelycontrolled.

Low loss

The multi-layer magnetic shielding structure effectively suppresses leakage flux andreduces eddy current losses,minimizing stray losses. The precision electromagneticshielding design simultaneously optimizes temperature rise and energy efficiency,ensuring long-term safe and stable operation.

Low noise

Both the core and active part are designed with vibration-damping pads,incorporating a multi-point positioning structure to effectively reduce operationalvibrations. This achieves noise levels significantly below standard requirements.

Reliability

By utilizing premium insulating materials combined with our proprietary insulationstructure design and advanced manufacturing processes, we ensure reliable electrical clearance under high voltage conditions.

Low temperature rise

With proven design excellence and robust construction, the product featuresstringent temperature rise control, delivering a service life far exceeding nationalstandard requirements.

Low loss

The 3D wound core structure ensures perfect alignment between the magnetizationdirection and silicon steel grain orientation,eliminating flux distortion at jointsinherent to conventional laminated cores. Combined with full annealing process, thisachieves a remarkable process coefficient of 1.01-1.05- representing an 8-12%reduction compared to laminated cores-while delivering superior magneticuniformity, lower no-load losses, and higher energy efficiency.

Low noise

Both the core and active part are designed with vibration-damping pads,incorporating a multi-point positioning structure to effectively reduce operationalvibrations. This achieves noise levels significantly below standard requirements.

High reliability

Through optimized design calculations, we precisely adjust winding ampere-turnbalance to minimize leakage flux. By calculating and analyzing short-circuitelectrodynamic forces and adding additional support points, we enhance themechanical strength of the windings. This ensures that the windings of thetransformer will not deform or shift during short-circuits.

Compact structure

Through continuous performance monitoring during field operation, we adopt aresults-driven approach to iteratively optimize product design, eliminate potentialflaws, and enhance reliability and durability.

Low loss

reluctance uniformity by 40%,reducing no-load current by 60-80%.No-load andload losses are decreased by 25% and 15% respectively, achieving high efficiency andsuperior short-circuit withstand capability.

The wound core's seamless 3D magnetic circuit structureimproves magnetic

Low noise

Through structural optimization across multiple stages - including core fabrication,coil winding, active part clamping,and lead clamping - combined with stringentmanufacturing process control, the transformer achieves a significant reduction inambient noise impact.

High reliability

Through optimized design calculations, we precisely adjust winding ampere-turnbalance to minimize leakage flux. By calculating and analyzing short-circuitelectrodynamic forces and adding additional support points, we enhance themechanical strength of the windings. This ensures that the windings of thetransformer will not deform or shift during short-circuits.

Details Images

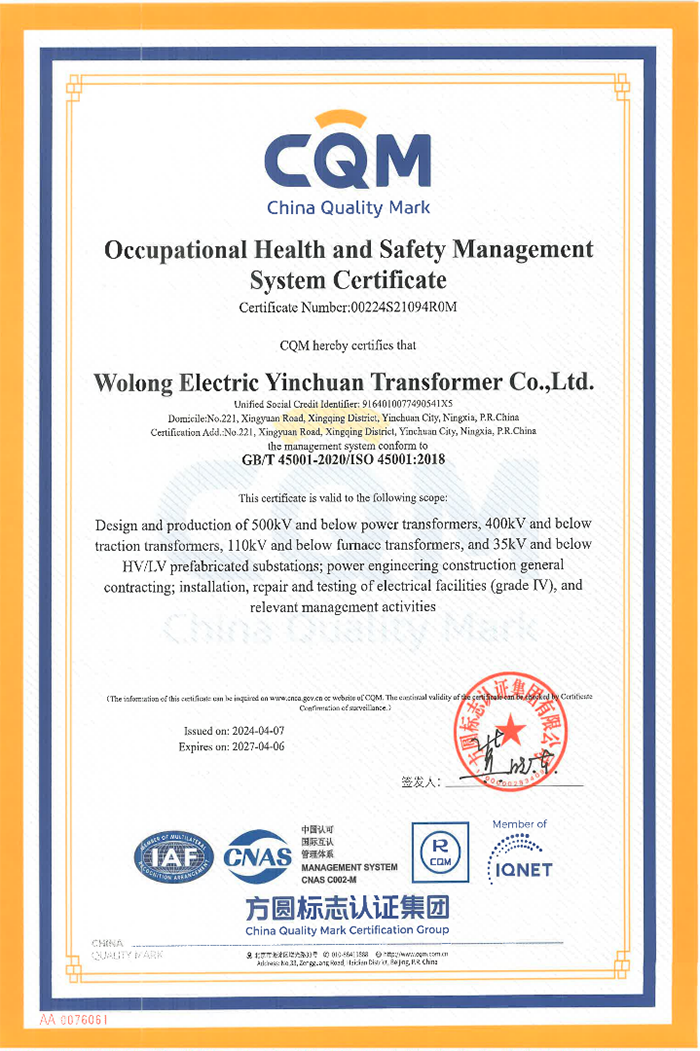

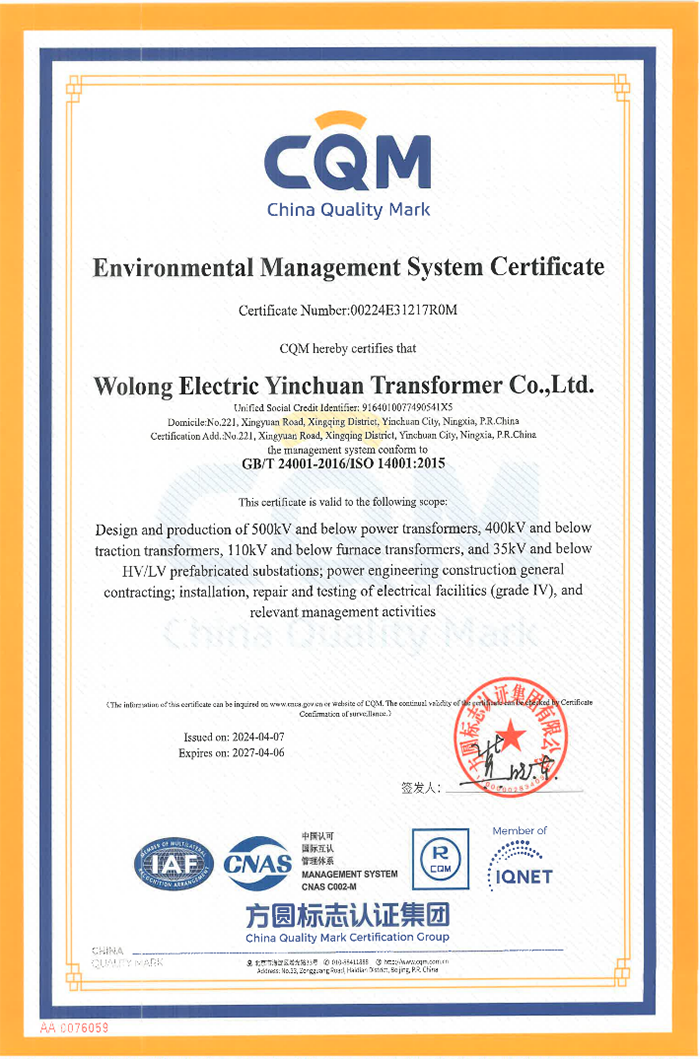

Certification

ISO Management System Certificates

ISO Management System Certificates

ISO Management System Certificates

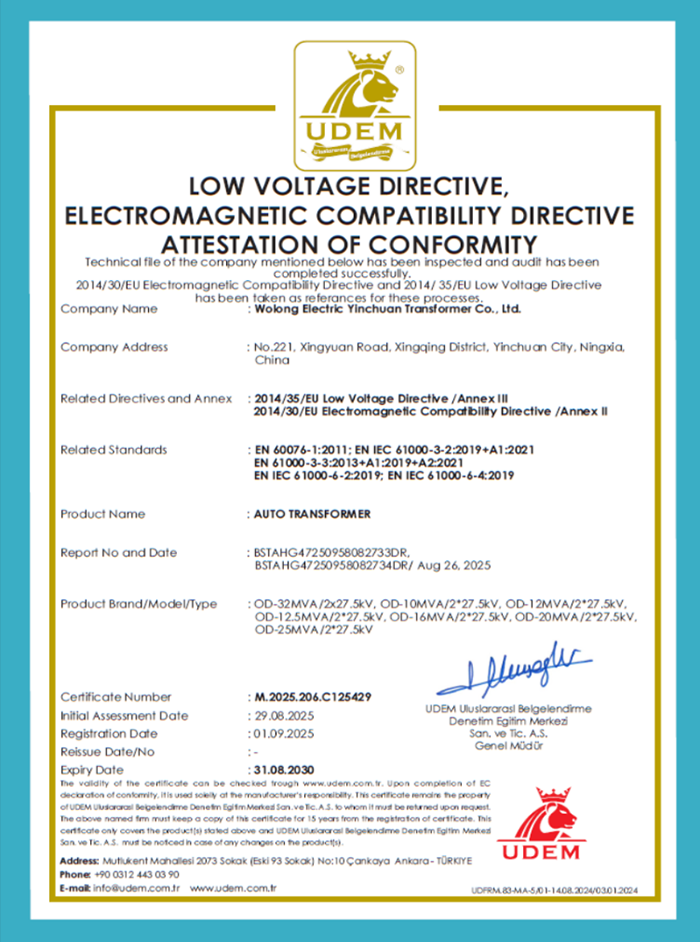

CE certificate

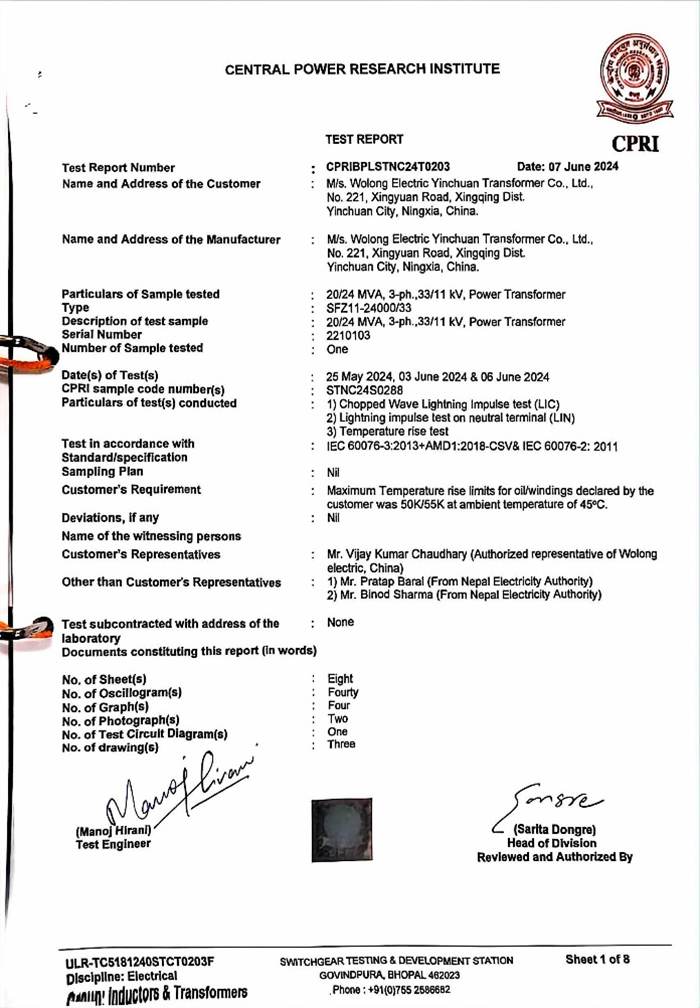

Test Report issued by CPRI

Test Report Accredited by CESI

Packing

Large Oil-immersed Transformer Main Body: Naked Packing

Large Oil-immersed Transformer Components: Wooden Case Packing

Small Oil-immersed Transformers: Steel Frame Packing

Transformer Oil: Pallet

Dry-type Transformers: Wooden Case Packing

Delivery

EXW

FCA in the exporting country

FOB at the port of shipment in the exporting country

CIP to the port of destination in the importing country

DAP at the project site in the importing country (for some countries)

Road Transport

Railway Transport

Sea Transport (Bulk Carrier Shipping/ Container Shipping)

Company profile

Wolong Electric Yinchuan Transformer Co., Ltd. was established in 1968 and is located in the Xingqing Science and Technology Park in Yinchuan City, Ningxia Hui Autonomous Region. It is a key backbone enterprise in Ningxia and a member unit of the Transformer Industry Association. It covers an area of 200 acres and has a modern factory of 80,000 square meters with an annual production capacity of 18 million kVA. The company specializes in the research and development of various transformers with voltage levels below 500KV and capacities below 500MVA, including power main transformers, traction transformers, electric furnace transformers, rectifier transformers, mine transformers, distribution transformers, European-style box substations, American-style box substations, Chinese-style box substations, and container substations, etc. There are hundreds of varieties and specifications. Products are widely used in high-speed railways, electrified railways, national grids, the top five and sixth power generation groups, new energy power stations, energy storage charging, petrochemicals, coal, steel smelting, water conservancy and hydropower, public utilities and other industries. The company is the mainstream supplier of the national railway group, a qualified supplier of the national grid, and a qualified supplier of the top five and sixth power generation groups. It has now developed into a comprehensive service solution provider integrating transformer manufacturing, power equipment integration, EPC general contracting, and power system operation and maintenance. Products and engineering performance are distributed in more than 30 provinces, municipalities, and autonomous regions in China and are exported to more than 50 countries and regions in Asia, Africa, and Latin America.

Product introduction:

Transformer

A device that uses the principle of electromagnetic induction to change the alternating voltage, consisting of a primary coil and a coil. When alternating current flows through the primary coil, it will produce an alternating magnetic field in the iron core, and then induce an electromotive force in the secondary coil. changing the turns ratio of the coil, the voltage can be increased or decreased.

Strong overload capability: Able to cope with over-load transient large current operation conditions;Strong short-circuit resistance: In the event of a short-circuit fault, it can protect the transformer from damage;

Low temperature rise: In the event of-load, it has good heat dissipation, ensuring the life and safety of the equipment;

Low loss: The energy loss during the energy conversion process is small, improving the energy;

Low noise: The noise generated during operation is low, which is conducive to environmental protection.

Structural features

(1) Transformer iron

The core is made of high-performance electrical steel, cut by a shear line imported from Switzerland, with a burr of less than 0.0 mm at the cut, and adopts a non-laminated yoke process and a plate-type clamping structure, which effectively reduces the transformer's no-load loss and the mechanical strength of the core. The core can adopt single-phase double-column, single-phase three-column, three-phase three-column, three-phase fivecolumn and other structural forms.

(2) Transformer winding

The high voltage winding is wound by high density paper insulated compound conductor, and the low voltage winding is wound by self-adhesive interleaving conductor The winding span is designed with “0” margin, and the densification treatment of the pad block is adopted to enhance the mechanical strength and short-circuit resistance of the winding The oil flow guide structure is arranged inside the winding to improve the oil flow path and velocity, reduce the temperature rise at the hottest point of the winding, slow down the insulation aging, and extend the service life of the transformer.

(3) Transformer core body

The transformer body uses an overall suit process, with all windings dried separately, adjusted in height and shaped before secondary drying, ensuring that the coil height is uniform and consistent, and improving the ability to resist short circuits. After assembly, a vapor phase drying process is performed, which has a higher drying efficiency and cleanliness.